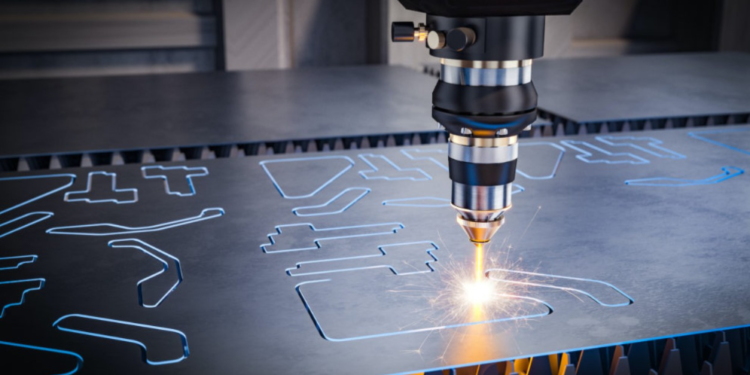

Accuracy and precision are two important factors when operating CNC machinery for sale. This enables the machines to make parts of different sizes and shapes with tight resilience. The CNC machinery uses specific codes to reshape the parts with an extraordinarily smooth surface. The job done by the CNC equipment is guaranteed, with accurate repeatability and at high volumes.

Understanding the Precision and Accuracy of CNC Machinery for Sale

Business owners should understand the difference between the accuracy and precision of CNC machinery. The accuracy and precision can be explained by an example in which you attempt to hit the target. Accuracy means hitting the nearest target, and precision is that you hit the bull’s eye target.

The accuracy of CNC machines means that the material will be cut from the materials closest to the design. Precision is that the equipment at CNC machine shops in Georgia will cut the exact structure of the product.

What Precautions to Take When Doing CNC Precision?

CNC machines have accuracy and precision that are more secure than manual machines. But ignorance, carelessness, and neglect in maintenance and repair can cause terrible accidents. Below are three points that must be followed to ensure safety during the precision process of CNC machines.

Safety Measures at the Machine Shops in Georgia

Mechanics operating industrial machine tools should take certain precautions when handling CNC machinery. This will ensure their safety and those who are around the equipment.

1. They should not move or walk hurriedly throughout the shop because picking up the pace can cause workers to lose their balance, and they could fall.

2. Workers should keep their arms folded or in their pockets when they are around machines and not operating them. This should be done to avoid injury to the hands and arms.

3. The shop management should only allow concerned workers to be present during operations.

4. The administrators should keep the equipment and machines in the right condition. If any apparatus gets harmed during its utilization, teach the workers to discuss it with their supervisors.

Worker Wearing the Right Attire and Security Equipment

The company’s managers must provide the right safety equipment and attire to the employees handling CNC machines purchased from shops like Flint Machine Tools.

1. The employees should wear proper hearing protection equipment.

2. It is important to wear appropriate working shoes. They should avoid wearing long sleeves and loose clothes. This will help prevent unexpected accidents.

Machine Shops in Georgia Practicing General Safety Measures

During the precision process, the equipment, employees, and the shop’s general safety must be observed.

1. A spotless working environment should be available to ensure safe operations. The shop should be cleaned regularly before and after the shift. The leftover garbage and debris are like fine metal pieces or chips.

2. Ensure that the laborers know all safety instructions and working techniques before beginning any activity.

3. They must be instructed to audit all CNC machines and their working techniques.

4. When operating, the CNC machines can be left unattended. But operators should always check the machines from time to time.

5. Avoid using a machine that has defects, and that is damaged.

6. The operators should avoid doing modifications unless a supervisor is present. The machine might develop issues if not taken the right care.

Consequences of not Taking Precautions During Precision Process

Neglecting to follow security procedures can have severe consequences. The consequence can be that accidents will occur more often. This will influence the general efficiency of machining shops. The result will be that productivity will decrease and affect the company’s profits.

So, it is important to have precision done with the CNC machining tools immediately from specialist organizations. The precision and accuracy of all CNC machines can be done. Also, businesses can find proper shops that provide the best maintenance, repairs, and precision services. Companies need to see these shops and follow the safety measures mentioned above to avoid issues with the CNC machinery for sale.

Below are three questions that will help you understand the concept of precision and accuracy of CNC machines.

Frequently Asked Questions

What are the tolerances of CNC machines?

The tolerance of CNC machinery for sale means how much work pressure the machine can bear and the threshold of the working operations. The machinery manual includes details on how much the machinery can work and when it should be replaced.

What is a CNC machine do?

The Computer Numerical Control machines will cut, grind, mill, and lathe different materials to create various objects. A computer program converts the 2D or 3D design into codes, and this data is transferred into the CNC machines.

Is CNC a hard job?

It can be challenging for the operators to handle CNC machines. But with proper training, the workers can gain precision.

Also read techmagazines